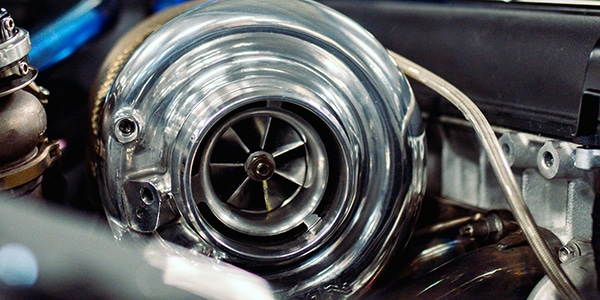

Engines have gone through an array of changes over the last 50 years as manufacturers have tried to develop clean, fuel efficient, high horsepower engines.

Turbochargers are ideally suited for this purpose. In the past, lower quality oil and lack of maintenance led to the premature failures of many turbo units. As modern engine design has turned increasingly to the use of turbochargers, it has become imperative to depend on oil that is both high quality and durable to protect this vital component.