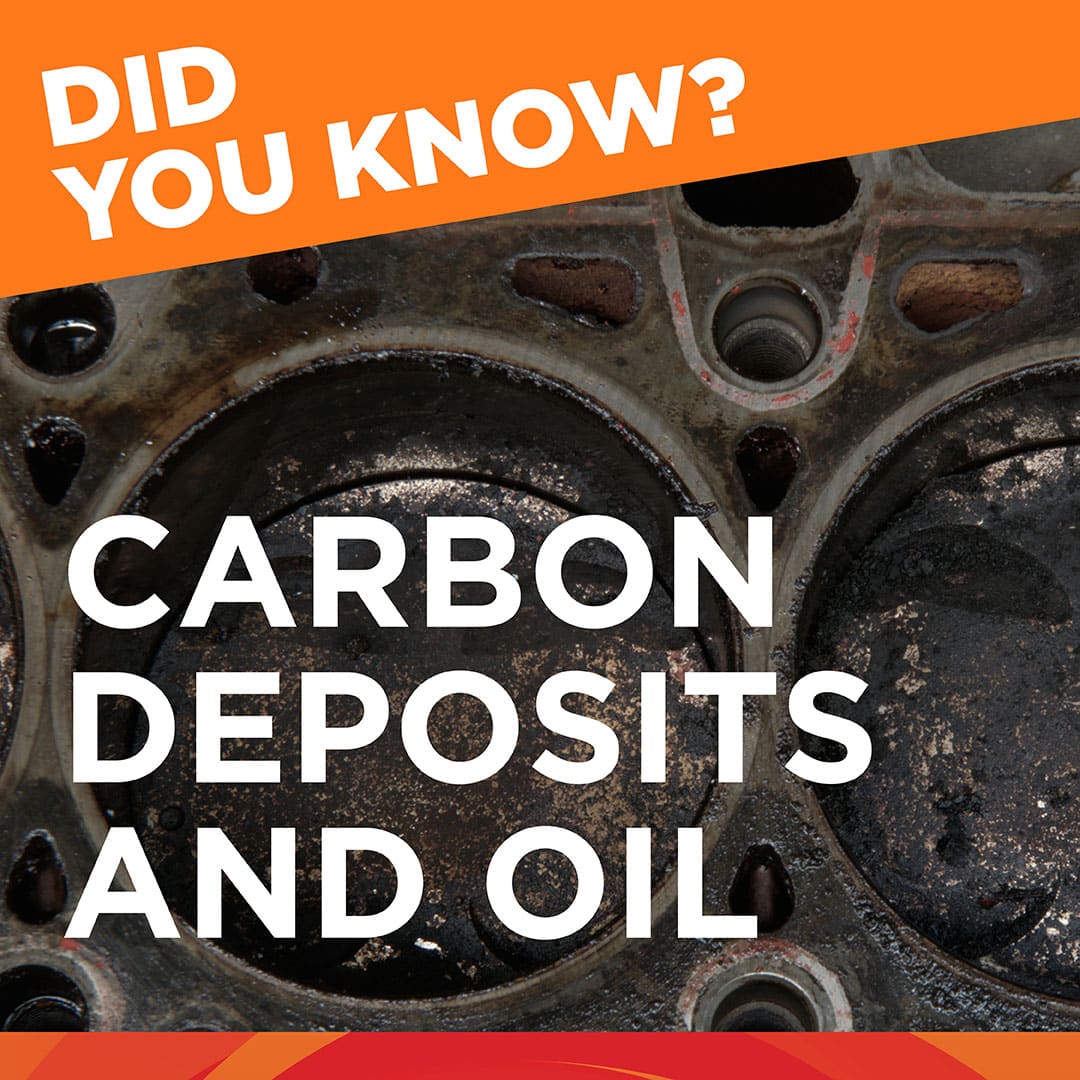

Most people in the automotive world are familiar with carbon deposits in engines and the negative effect these deposits have on components. What may be less understood is how and why these deposits are formed, and a few easy solutions to this problem.

Carbon Deposits and Oil

Background

First, highly refined and quality base oil (fully synthetic} is made of carbon molecules with strong bonds, and long chains in which the molecules are uniform in size and shape. Carbon deposits are also present in some oils and fuel but their chains are short and random in size. These shorter, random chains of molecules want to attach to each other and hot engine surfaces. If the particles become large enough, they can be seen with the naked eye.

As oil quality improved and synthetic oil became the standard, carbon deposits were reduced. Due to changing engine designs, the issue has resurfaced. Most auto manufacturers produce direct-injected engines because of their compact size, increased performance, and fuel economy. Direct injection comes with an important negative side effect: increased carbon deposits.

How Carbon Deposits Form

The carbon deposits occur because of the high efficiency of the direct injection engine. Unlike older gas engines that sprayed fuel into the intake manifold where it mixed with air, direct injection sprays fuel directly into the combustion chamber, skipping the intake system, along with the cleaning step for the manifold and intake valves that it provided. The fuel, and the detergents in it, bypass the intake valves and don’t clean them like in a traditional gas engine.

Direct injection also creates what’s known as a very “lean” gasoline mixture, which contains more air. Lean-burning direct injection engines are able to consume fuel more efficiently by using higher compression ratios, which leads to higher fuel efficiency and reduced emissions. Those same higher compression ratios cause oil that finds its way into the combustion chamber, past the rings, valve stem seals, or PCV system to be quickly consumed and changed into carbon deposits. These growing carbon deposits cause air to tumble as it enters the cylinder, creating uneven distribution and an erratic flame front, which leaves unburnt fuel and hot spots, leading to increased carbon deposits.

High combustion pressure is also present in a direct injection engine, which aids the build-up on intake valves and other parts of the engine. These engines can have variable valve timing and even cylinder deactivation. The engine management system can control, among other things, when and how long the valve is open and exposed to combustion byproducts or unburned fuel, which again aids in the creation and buildup of these deposits.

Oil’s Role in Deposits

But engine oils can, depending on quality, help to combat carbon deposits. Additives in premium oil blends can help break down, disperse, and even encapsulate the deposits, holding them in suspension until the oil is changed. But additives and oils break down over time and lose their effectiveness at controlling carbon deposits.

The engine oil lifespan is controlled by the quality of the base oil and additives used in the blend. All oil components are not the same.

One other important factor to oil lifespan is how the vehicle is used. If towing, taxi, offroad, or commute traffic are regular activities, these conditions call for increased oil changes.

Carbon Deposit Remedies

As mentioned, today’s engines have unique timing cycles leading to valves into the combustion chamber, with increased temperatures and compression ratios, and this causes more stress on the oil. If the oil is not up to manufacturer standards, then the oil can be a contributor to the carbon deposit problem. This is one reason manufacturers have introduced more new oil specifications over the last 15 years.

One of the simplest remedies to the carbon deposit issue is preventative maintenance. Regularly scheduled oil changes with high quality oil is imperative. This helps to ensure the cam actuators are working in optimal condition to control the valve exposure in the cylinder.

Also, higher quality oils have lower volatility which reduces the volume of vapors in the crankcase, which find their way into the combustion chamber.

Lastly, a fuel tank additive can be use to aid in keeping the injectors clean so that they can deliver the precise amount of fuel in the correct spray pattern.

How ENEOS Helps

As an OEM factory fill developer and supplier, ENEOS is proud to offer high quality oil with premium additives in the correct measures for today’s engine technology. Working directly with automakers, ENEOS helps create the specifications for many engines on the road today. Drivers can trust ENEOS to contribute the special benefits oil is intended to provide because of our relationship with manufacturers, and our long-term obsession with providing quality and innovation.

[Part # 3701-300]