Did You Know: What is an e-Axle?

Part one of our exploration of e-Axle technology and how to service them.

In the ever changing automotive world one of the newer changes has been to the drivetrain and its components. One of these is the e-Axle.

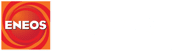

An e-Axle (electric axle) is a self-contained drive unit that combines:

- Electric motor (traction motor)

- Power electronics (inverter/controller)

- Transmission/gear reduction

- And often the differential

…all in one compact housing that bolts directly to the vehicle’s axle.

Think of it as the electric equivalent of a transaxle in a front-wheel-drive car—motor, gearing, and differential, all in one package, just driven by electrons instead of gasoline.

Why E-Axles Were Developed

They came about for a few reasons:

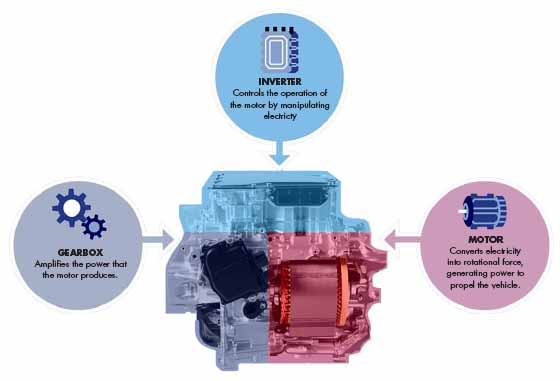

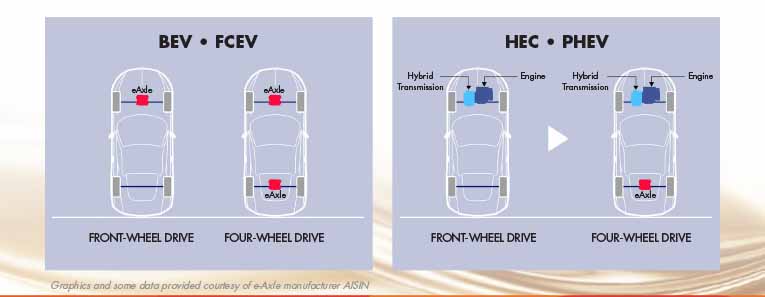

- Packaging efficiency – Instead of running a long driveshaft from a central motor, you put the motor right at the axle. This saves space and weight.

- Scalability – Automakers can add one to the front, rear, or both axles for AWD without redesigning the whole drivetrain.

- Cost reduction – One integrated unit is cheaper and lighter than multiple separate components and requires less assembly.

- Performance – Shorter power path from motor to wheels = faster torque delivery and better control.

Modularity for different platforms – Same unit can be used in different models with minimal changes.

EDU vs. EDM

These terms get thrown around interchangeably, but they have slightly different meanings in engineering circles.

- EDU (Electric Drive Unit)

- General term for a complete propulsion unit: motor + gearbox + inverter.

- Can be mounted at the axle (making it an e-Axle) or somewhere else in the vehicle with power sent to the wheels via driveshafts.

- Used in both hybrids and full EVs.

- EDM (Electric Drive Module)

- Usually refers to the motor + gearbox portion without the inverter, or with less integration.

- Often paired with a separate power electronics module located elsewhere.

- More common in hybrids or PHEVs where space and cooling constraints dictate splitting up components.

Application Examples

Application

- Full Battery EV (e.g., Ford Mach-E, Tesla Model 3)

- AWD add-on (e.g., Volvo “e-AWD” hybrids)

- WD add-on (e.g., Volvo “e-AWD” hybrids)

- PHEV or HEV (e.g., Toyota RAV4 Prime, Honda Accord Hybrid)

- Commercial EV trucks

Typical Use

- E-axle / fully integrated EDU

- Rear EDM with separate inverter

- EDU split layout

- Heavy-duty E-axle

Rationale

- Packaging and efficiency—everything’s in one unit at each driven axle.

- Rear electric drive is simpler and uses existing front-engine drivetrain.

- Motor and electronics separated to fit in existing engine bay and use existing axles.

- Robust, high-torque, and easier to scale up for big payloads.

Quick analogy

- EDU: The whole pizza—crust, sauce, cheese, toppings—in one box.

- EDM: Just the crust and toppings—sauce (inverter) comes in a separate packet

Smaller and lighter components allow the vehicle to run longer with less energy and make better use of available space. Small and powerful eAxle brings many benefits also to vehicle users.

—AISIN, e-Axle manufacturer

In the end expect to see many more vehicles with this technology coming into your shop.

Part two: current e-Axle vehicles and recommended fluid change intervals – coming soon!

ENEOS e-Axle Fluid [Part # 3010-311]

DYK: What is an e-Axle? [PDF for download]

View part 2: DYK About e-Axle Models and Maintenance?