Modern advancements require evolving partner technology to help properly maintain and extend the life and optimal performance of vehicles. In this article, we review one of the engine issues that has come about in the last several years due to changes in performance technology, and how lubricant manufacturers help to solve it: Low-Speed Pre-Ignition.

Did You Know?

WHAT IS LOW-SPEED PRE-IGNITION

(AND HOW TO PREVENT IT.)

What is Low-Speed Pre-Ignition?

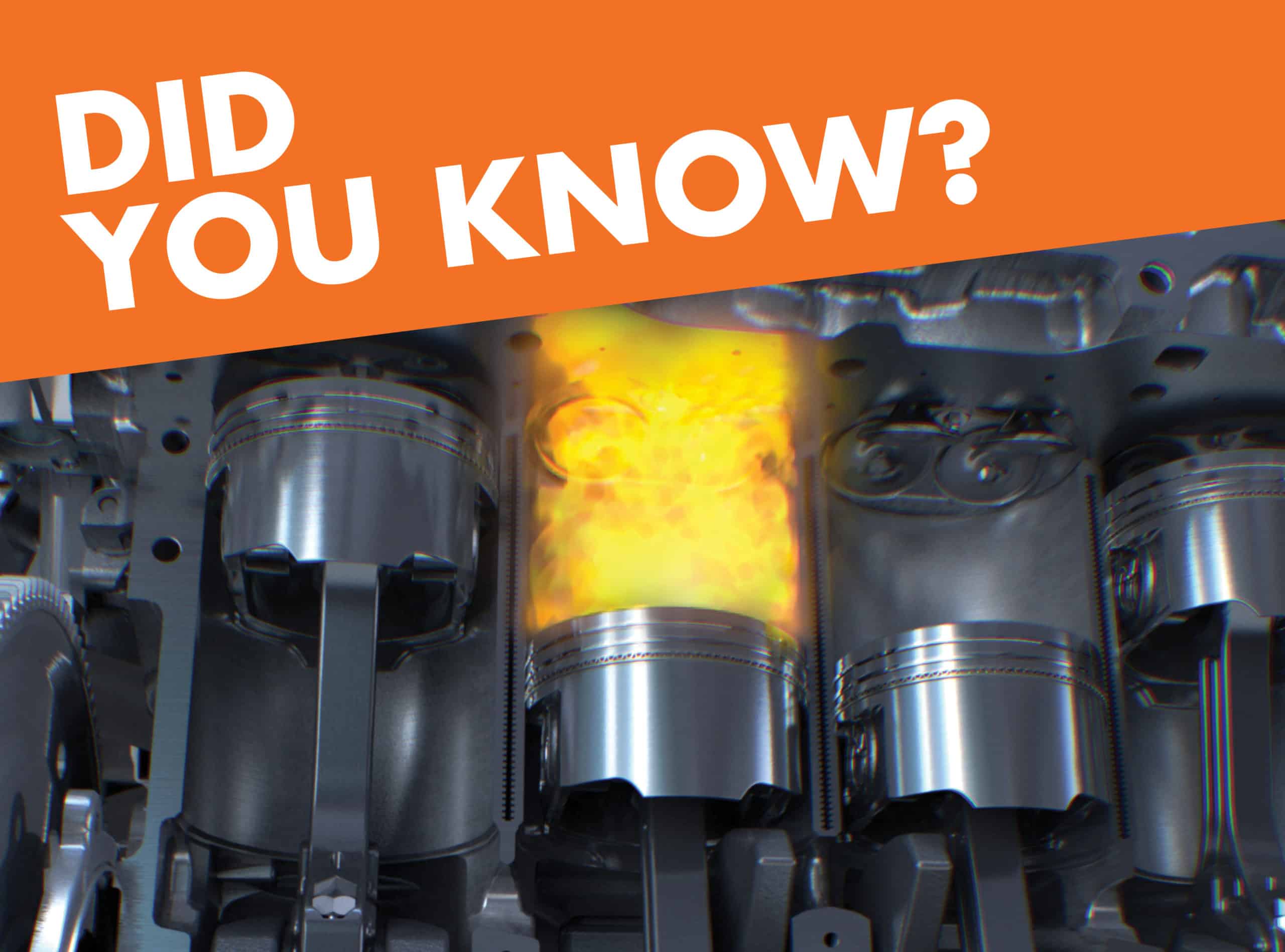

Low-Speed Pre-Ignition, or LSPI, occurs when the fuel mixture ignites prematurely, before the piston is at the top of its stroke when the spark plug fires. It most commonly occurs in certain direct-injection turbocharged vehicles while at low speed and high loads.

LSPI came about as manufacturers replaced large conventional engines with Turbo Gas Direct Injected (TGDI) engines for improved fuel economy and performance. The higher power density of these compact designs made them prone to LSPI. This can create extremely high cylinder pressures and mild to heavy knocking. When severe enough, the explosion pressure can destroy pistons and connecting rods.

Unlike a conventional knock, an LSPI event cannot be predicted, so it cannot be prevented by adjusting spark timing. Research has shown that mitigating pre-ignition involves altering the engine design or lubricant to help avoid the issue.

How engine oil impacts LSPI

There are several factors that contribute to LSPI and engine oil has been observed to be one. Small droplets of oil can enter the combustion chamber in the area between piston and cylinder wall and auto-ignite, causing an LSPI event. Research has found that oils with higher levels of calcium in the detergency additive tended to increase the frequency of LSPI, whereas magnesium-based detergents do not seem to promote LSPI.

There are other additive and lubricant compositions that can also influence LSPI. Both the quality of base oil (Group II vs. Group III) and the viscosity can have secondary effects on LSPI. The effect on LSPI from these other aspects are not as significant as the detergency additives, but can change the LSPI frequency in oils that are more prone to promote LSPI.

How to prevent LSPI?

The easiest way to remedy is through engine lubricants. New testing and certification by the International Lubricant Specification Advisory Committee (ILSAC) has addressed this problem in their latest specification, GF-6, which incorporates new technologies to help prevent LSPI. All oils with ILSAC GF-6 approval are formulated to address LSPI. Additionally, many OEMs are developing their own in-house LSPI tests for their engine designs.

In the move to GF-6, oils will be broken into 2 categories, GF-6A and GF-6B. GF-6A will apply to 0W-20, 5W-20, 5W-30, and 10W-30. GF-6B will only apply to 0W-16. Along with this change to address LSPI, GF-6 has made improvements in many other areas as well that we will cover in other articles.

ENEOS has adjusted our primary line of Motor Oil products to meet the ILSAC GF-6 requirements, and of course, the highest quality standards. As the largest OEM Asian oil supplier, ENEOS creates advanced lubricants with vehicle engineers to provide optimum fuel economy with maximum power and long-term protection.